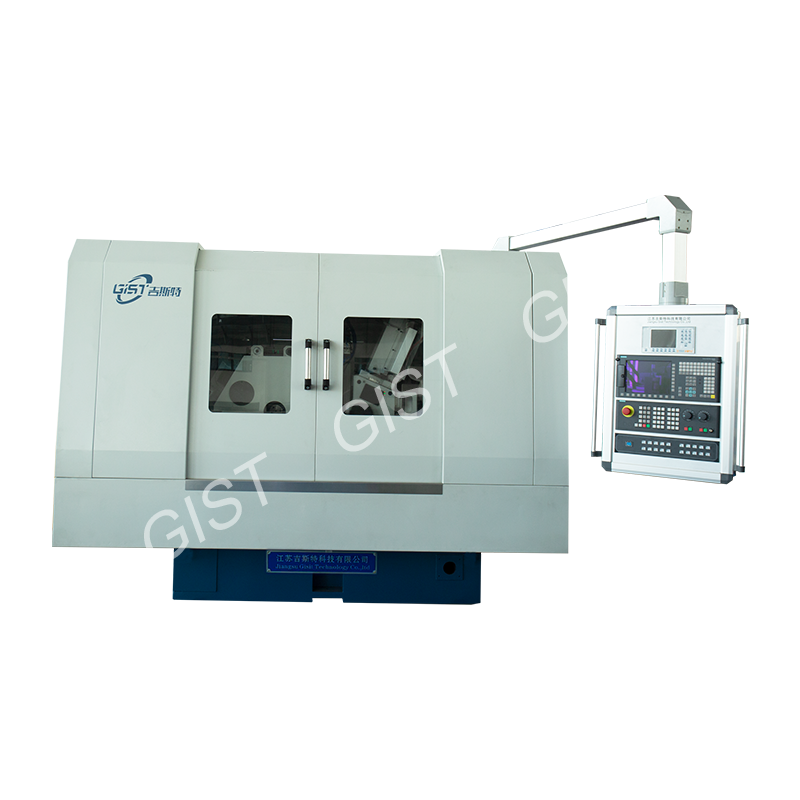

Products

Electrical upsetting machine

Category:

Overview:

The company implements and implements various system management requirements, continuously innovating and improving to meet the comprehensive needs of customers.

Keyword:

Rod Centerless Grinder, Fine cone grinder

Product Details

The electrical upsetting machine operates by passing an electric current through a metal billet, which generates resistive heating and causes the metal to become hot enough for deformation. The high temperature generated during this process allows for rapid and uniform heating of the metal, making it easier to forge and form into desired shapes.

One of the main benefits of using an electrical upsetting machine is its ability to produce forged parts with improved mechanical properties compared to traditional forging methods. By applying high electrical currents to the metal, the grain structure of the material can be refined and aligned, resulting in stronger and more durable finished products. Additionally, electrical upsetting can reduce or eliminate the need for secondary processing steps such as annealing, further improving overall manufacturing efficiency.

Another advantage of electrical upsetting is its energy efficiency. Since the process relies on resistive heating rather than external sources of heat, it can consume significantly less energy than other forging techniques. This not only reduces operating costs but also helps to minimize environmental impact by reducing carbon emissions associated with energy consumption.

Finally, electrical upsetting provides greater control over the forging process, allowing for precise shaping and sizing of metal components. By adjusting the intensity and duration of the electrical current, manufacturers can fine-tune the deformation of the metal to achieve specific dimensions and tolerances. This level of precision can help ensure consistent quality in the final product and reduce waste due to rework or scrap.

Previous

Previous

Online Message

Mobile Website

Hot Keywords

Total length cutting machine,

Rod end face grinding machine,

Lock clamping slot grinding machine, General grinding wheel taper grinding

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans